Brixton Windmill

A few hundred metres from the bustle of central Brixton, down a suburban street is a surprisingly rural scene.

In the middle of Brixton there is a 200 year old windmill from which you can buy freshly ground flour.

People who have lived in London for years are amazed to discover Brixton Windmill. The schedule of the windmill’s open days can be found on their website from where you can book the guided tours.

There is another windmill in Upminster (pictures to be posted) and another in Shirley, Croydon.

The Windmill

The windmill’s brick tower is a cone on which is mounted the cap, looking like an upturned boat. The wooden cap structure contains the machinery that takes the wind’s power caught by the sails to turn the millstones grinding the wheat into flour. The whole cap rotates on a ring to turn the sails into the wind.

Some windmills user a weather vane to keep the windmill’s sails pointing into the wind, whereas the Brixton windmill has a small wheel. When the windmill is in operation, a loop of rope comes down from the wheel to ground level for the miller to change the direction the windmill’s sails are facing.

To keep the mill dry, the exterior is painted with tar. The tar stops the water penetrating the brickwork, but it also stops moisture from escaping the mill tower leading to damp patches. Test areas of brickwork have had their tar removed to see if the damp inside is improved.

Internally, the white walls are lime wash which has an anti-bacterial effect.

History

So how did the mill survive amongst all the urban sprawl of an expanding London? The windmill was operated by generations of the Ashby family until 1934. As a windmill, it was used continued in use until 1862 when there were so many buildings where previously there had been open fields had previously been open fields that the strength of the wind reaching the windmill’s sails was no longer enough.

The Ashby family decided to lease a watermill on the River Wandle and continued milling flour. In 1902 the family’s lease on the watermill expired and they returned to the windmill. Instead of using wind they installed a steam engine driving a new set of millstones. With the industrialisation of food production, the mill finally closed in 1934.

The windmill lay derelict until in 1957 the mill and some surrounding land was bought by London County Council to create the park we have today. Restoration happened in 1964 and the windmill was first opened to the public in 1968, with Lambeth Council taking ownership of the building in 1971.

Flour was milled again in 2014 for the first time since 1934.

The building and its environment have changed over the years. Looking carefully, a blocked up door can be seen along with a groove where the miller’s cottage abutted on to the mill. Also missing is the stage running around the exterior which would of been a couple of metres above the ground to allow easy maintenance of the sails. A doorway can be seen showing where it was located.

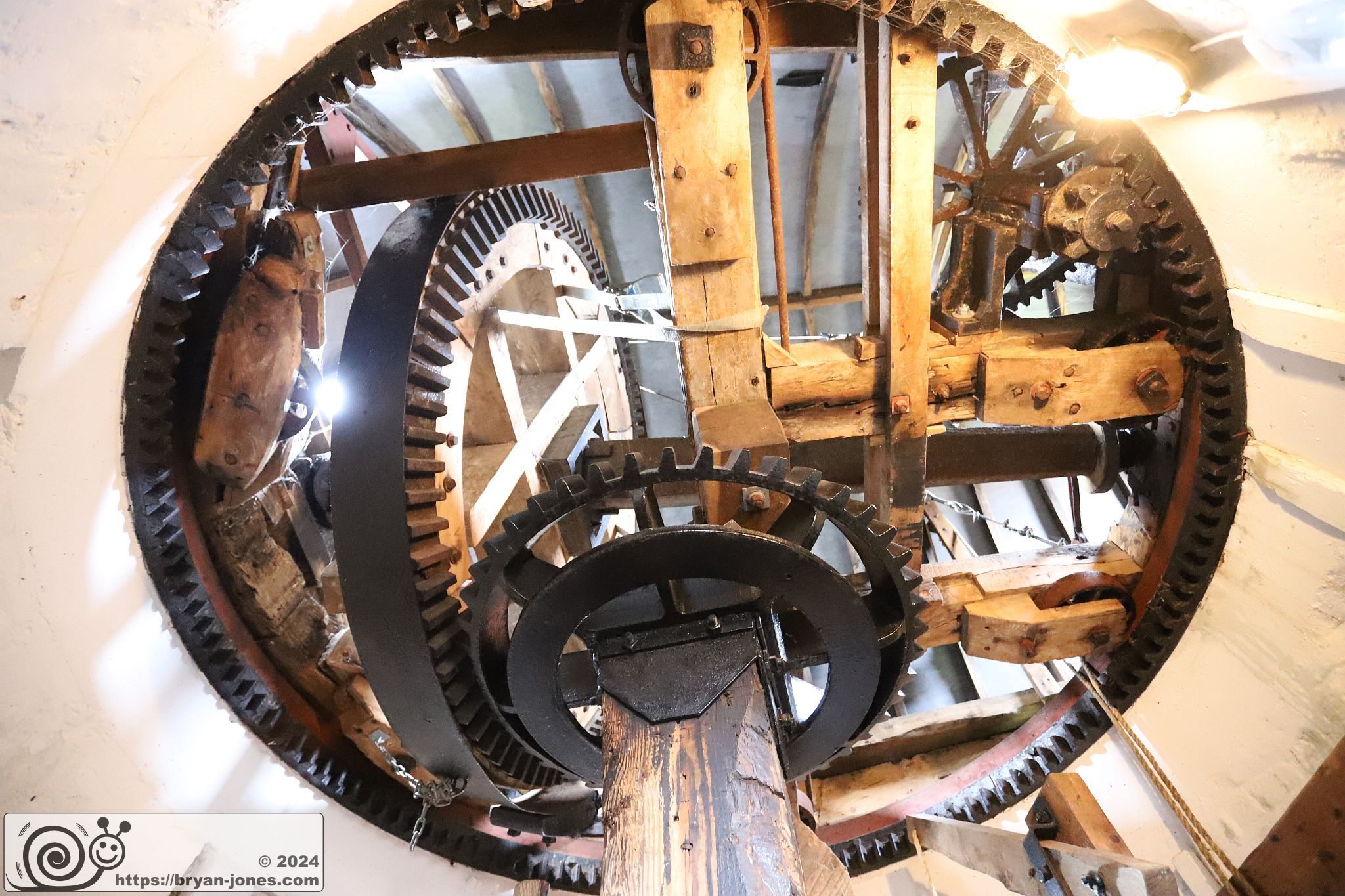

Fourth Floor & The Cap

The top of the windmill, looking like an upturned boat, contains the windmill’s machinery. The windmill’s sails turn in the wind and, through bevel gears, turn the shaft that runs down the centre of the windmill. The horizontal shaft on which the sails are mounted, through bevel gears, turn the vertical post running down to the second floor. The turning power of the vertical post, through more gearing, turns the mill stones to grind the wheat into flour.

The machinery’s gearing dominates the interior of the cap. The straps in the pictures are there to act as a brake so the windmill cannot start unexpectedly rotating in the wind. Windmills have always been susceptible to fire as the flour dust is flammable. One of the mill’s fire safety measures is in plain sight, but is not obvious until pointed out. The gearing along the shafts alternate between metal and wood as metal on metal could generate a spark with disastrous consequences. To make maintenance easier, the teeth of the wooden cogs can be removed individually and replaced.

Third Floor

The third floor of Brixton Windmill was used to store flour. Apart from the shaft passing through, this floor has no machinery.

Second Floor

The second floor is where the milling of flour happens. The wheat came down a chute into the hopper from where it dropped to the granite millstones to be milled into flour.

First Floor

The return of flour milling to the Brixton Windmill was not powered by wind, but steam. one of the buildings surrounding the wind mill contained a steam engine to power the mill stones in the black machine.

For safety, the steam engine was located outside of the mill (flour dust can explosively catch fire), the power being delivered to the millstones using belts.

There is some lovely rope work around the Brixton Wind Mill. The ball shaped knot used on the staircase ropes is called a Monkey’s Fist.

Millstones

The heavy granite stones have carefully carved grooves which carefully grind the wheat to produce the flour. One of the millstones can be seen close to the windmill’s door.