Markfield Beam Engine

Markfield Park is a green oasis in Tottenham bordering the River Lea which has a stinky past, a brown stinky past.

The park started off life as filter beds for Tottenham’s sewage where the brown goodness was processed into some commercial produce (yes, really) and the remainder that ran off into the river.

The sewage arrived at the site in underground sewers and the filter beds were above ground so something was needed to pump it to the surface – which is where the Markfield Beam Engine came in, pumping the brown festering ooze to the surface.

Today the beam engine is thankfully disconnected from the sewers and lovingly maintained by the museum who regularly run it in steam. It is near silent in operation apart from the gentle hiss of steam. There is no brake on the fly wheel that drives the pump, stopping it entails switching off the power and letting it spin to a stop of it’s own accord after a few minutes.

Visiting

The beam engine is free to visit with donations very welcome. Steaming days and opening times can be found on the museum’s website.

The Beam Engine

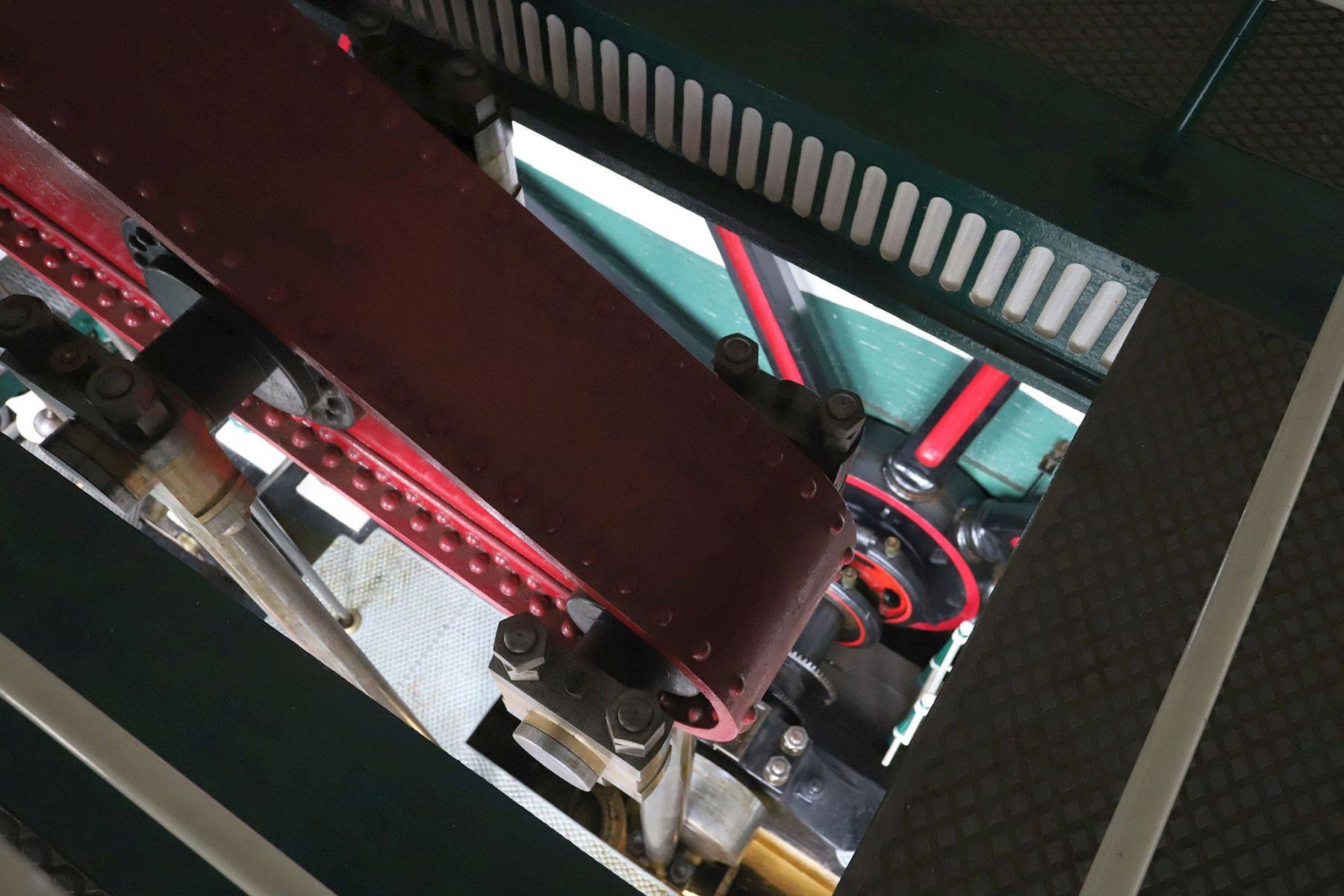

The engine is accessible on multiple levels. The engine is very large in a building not much larger which makes photographing it a challenge.

The picture shows (left to right) the cylinders in their wooden jackets, which are linked to one end of the red beam, the other end of which can be seen to the right descending through the platform with it’s coupling rods dropping down out of shot to the crank which drives the flywheel against the wall, it’s speed regulated by the governor (the device with the two brass balls attached to the diamond) in the centre left bottom of the photo.

The Cylinders

Steam enters the cylinders from the boiler. Within the cylinder is a piston which is driven up by the steam. The piston pushes the connecting rod, which is connected to one end of the beam, so pushing the beam up.

The Beam

The up and down motion of the pistons in the cylinders, driven by steam, drives the beam up and down via the two connecting rods. The third connecting rod drives the first of the two sewage pumps. The beam sits at the top of the engine and works in a seesaw arrangement; as one end goes up the opposite end is going down.

At the pump/flywheel end of the beam there are three connecting rods dropping back down to floor level. The first two transfer up and down motion to the second sewage pump and the third is linked to the crank which converts up and down motion into circular motion to drive the flywheel and the governor.

The Governor

The governor, without any electronics, automatically regulates the speed of the whole engine using centrifugal force and a clever steam valve. The faster the engine runs the faster the governor spins and the further out the brass balls come from the spindle by centrifugal force. An intricate valve within the governor cuts the steam as the brass balls fly further out, the slower the governor spins then the closer the balls spin to the spindle and so open the valve to let more steam into the engine. By this, the governor reaches an equilibrium and so the engine runs at a constant speed

The Basement

The basement is where the two sewage pumps are located.

The sump is below the walkway where the excess oil and water from the engine collects. The large pipe gives an idea of how much sewage was pumped with every revolution of the engine.

The Volunteers

There is a real enthusiasm shown by the volunteers who look after the engine and welcome visitors with all their questions.

The scale of the engine is huge.